-

Solution

-

WL-CSP Structure

and Characteristic -

WL-CSP New

Technology -

Reliability Data

Services

WL-CSP

Very small, thin package for smart phone/wearable

○Mold Type: Passed AEC-Q100 “G0” grade reliability test, and 18 years experience for automobile application

○Mold-less Type: Low profile 0.2mm Max. package height, 0.1mm fine pitch terminals

○Turn-key solution: RDL ~ singulation ~ electrical test ~ T&R packing

Cu RDL

Good solutions for power devices / high frequency devices

○Protect wire bonding damage by 15um thick RDL

○20% reduction of ON resistance compared with non-RDL

○Passive devices (inductor coil, etc.) with multilayered RDL

○High pin count with multilayered (2~3) RDL

Multi-Chip WL-CSP

Next generation package

○Multi-Chip structure by collaboration of RDL, Cu pillar and assembly technologies

○Low resistance due to short wiring compared with wire bonding connection

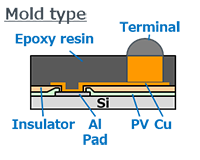

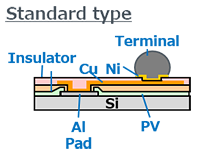

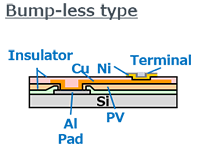

| Mold type | Mold-less type | |||

| Structure |  |

|

|

|

| Features | High reliability (AEC-Q100 G0) |

Low-profile Fine pitch |

For device embedded substrate |

Terminal forming on Al pads |

| PKG height(total) | 0.3mm~ | 0.2mm~ | 1.6mm~ | 0.2mm~ |

| Terminal pitch | 0.3mm~ | 0.1mm~ | - | 0.1mm~ |

| Terminal diameter | 150um~ | 75um~ | 75um~ | 75um~ |

| Terminal height | 60um~250um | 20um~250um | 6um~ | 20um~250um |

Options: Backside treatment (resin coating, mirror finish), Plating (SnAg, Au, Ni)

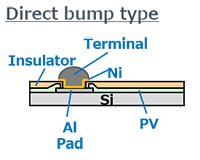

Terminal pitch / terminal height variation matrix

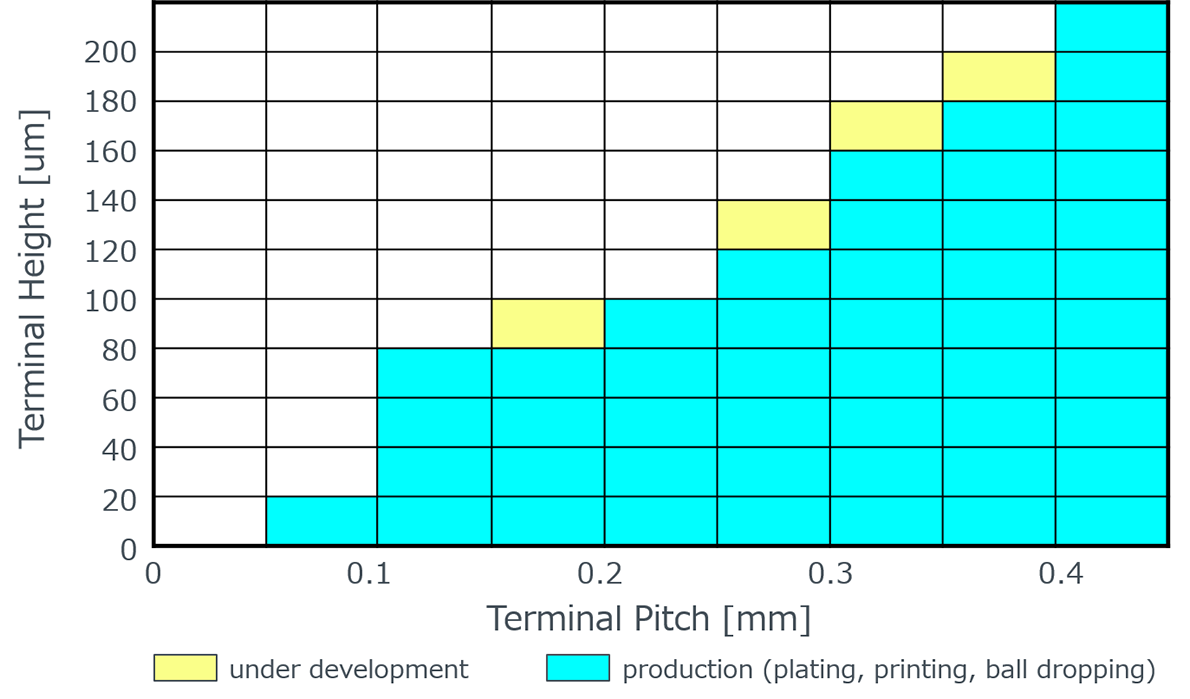

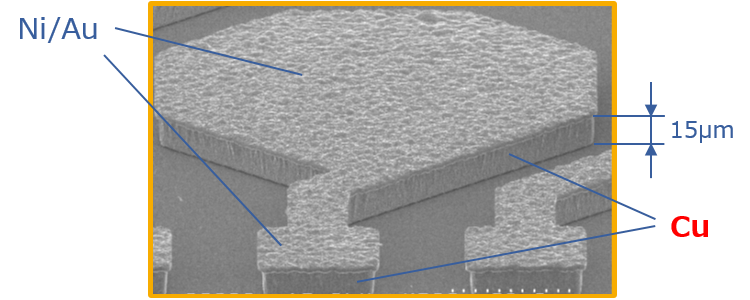

Thick RDL technology

Structure

Cu/Ni/Au thickness * : 15/3/0.5μm

* standard Cu thickness: 5μm

Cu Line & Space : 30/30μm

Feature

Protect wire bonding damage by 15um thick RDL

20% reduction of ON resistance compared with non-RDL

30% chip size shrink with POE (Pad ON Element) structure compared with non- POE

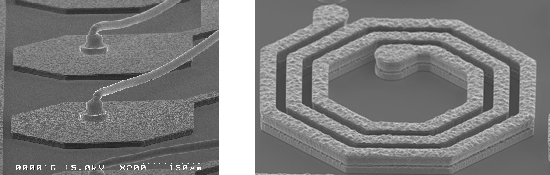

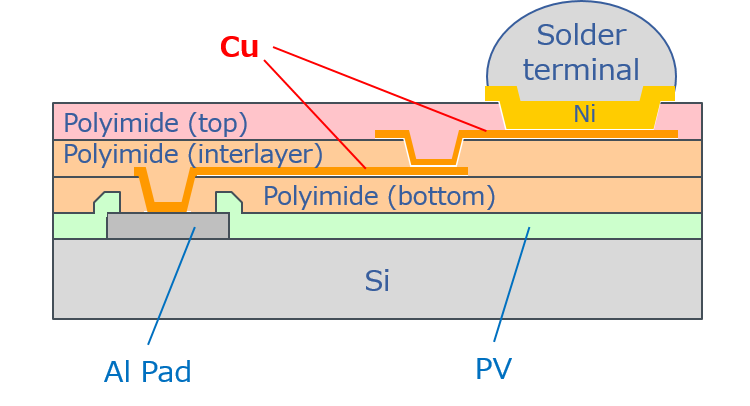

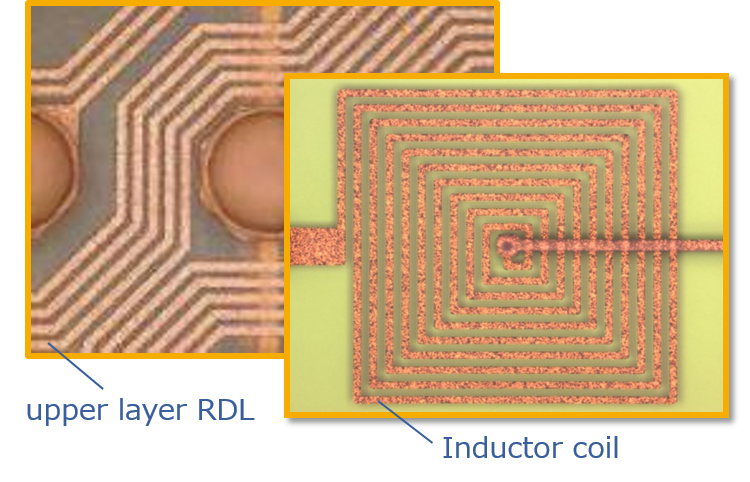

Multi-layer Cu RDL technology

Structure

Cu RDL :5μm

# of Cu layers :2~3

Polyimide :13μm

Cu L/S : 30/30μm

Feature

Embedded inductor coil by 2 layers RDL

High pin count with multilayered (2~3) RDL

Over 600V break down with 13um polyimide

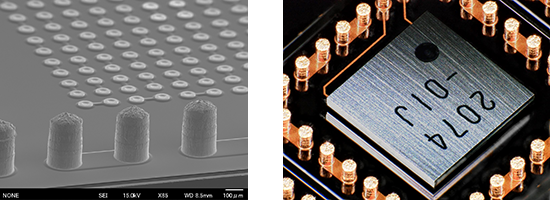

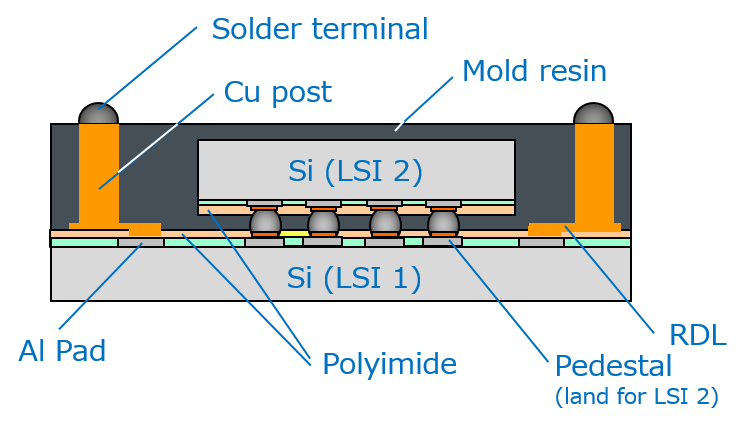

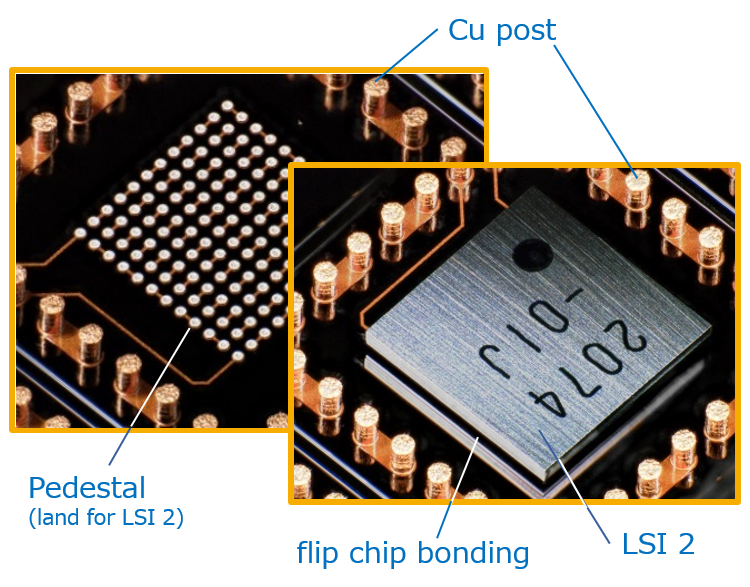

Multi-Chip WL-CSP technology

Structure

Cu RDL :5μm

PKG height :0.5mm Max.

Cu L/S : 15/10μm

Feature

Chip-size MCP by 300µm high Cu post technology

Low resistance due to short wiring compared with wire bonding connection

Reliability data (AEC-Q100)

■Mold Type ~ Grade 0 ~

| Test Category | Test Condition | Note |

| Pre-condition | 85℃/85% RH, 168H, reflow 260℃ | Package Level |

| High Temp. Storage | Ta=150℃, 2000H | Package Level |

| Temp. Cycle | -65℃~RT~175℃, 500cyc | Package Level & Board Level |

■Mold-Less Type ~ Grade 1 ~

| Test Category | Test Condition | Note |

| Pre-condition | 85℃/85% RH, 168H, reflow 260℃ | Package Level |

| High Temp. Storage | Ta=150℃, 1000H | Package Level |

| Temp. Cycle | -65℃~RT~150℃, 500cyc | Package Level & Board Level |

Services

○RDL layout design, photomask preparation

○Pb-free soldering (plating & paste printing & ball mounting)

○Wafer mapping (generating and merging data)

○Full turnkey solution

・RDL ~ Insulation layer ~ terminal forming

・Singulation

・Electrical test (logic & analog)

・Die inspection (6D)

・Tape and reel packing

・Options / Si backside treatment (resin coating, mirror finish), plating (SnAg, Au, Ni)

○Ship to customer in wafer form, T&R

Drop ship to final customer