Inside of Semiconductor Fabrication Plant

Our plant fabricates semiconductors. Semiconductors are incorporated into many devices indispensable to society, including electric home appliances and social infrastructure.

With the focus on high-mix low-volume production, we possess plenty of manufacturing processes. Our products are delivered to customers both at home and abroad via our own production control system.

-

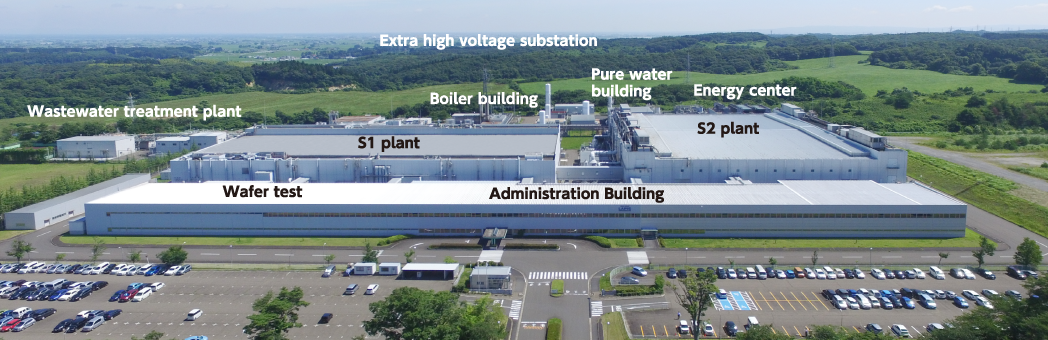

Factory introduction

-

Layout

Innovate State-of-the-Art Electronics

Besides dust control, temperature and humidity are maintained at a stable level inside the plant. Strict quality control is also carried out. Let us introduce the inside of our plant which has state-of-the-art equipment.

Temperature and Humidity Control of the S2 Plant

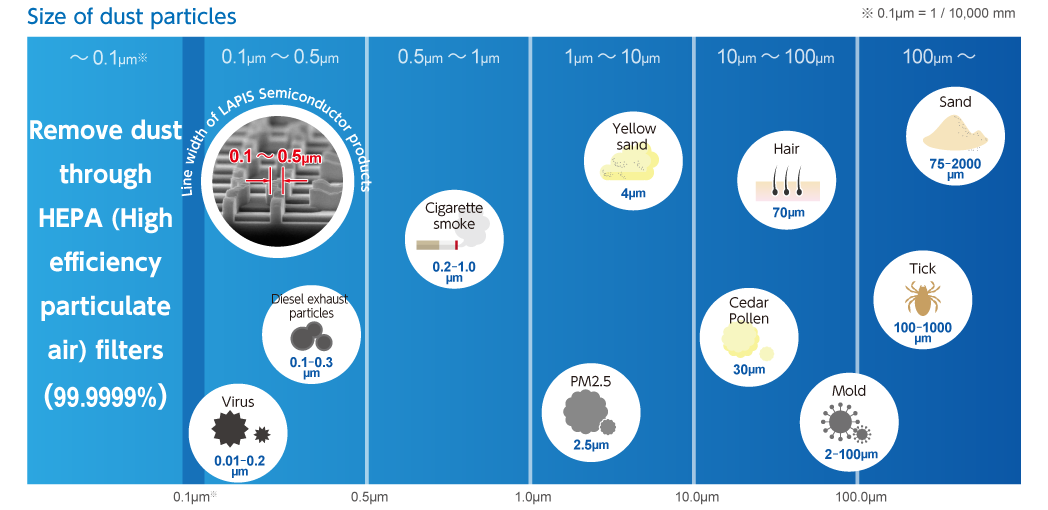

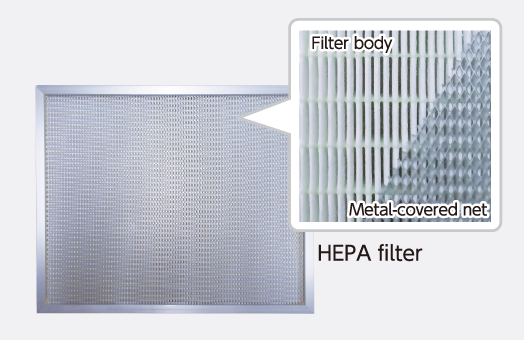

Cleanroom consists of walls, ceiling and floor made from special materials, where the air, through HEPA filters※, is constantly supplied and circulated. In order to keep positive pressure in the cleanroom, external air is partially pumped into the room.

※HEPA filter : ultra-high performance filter

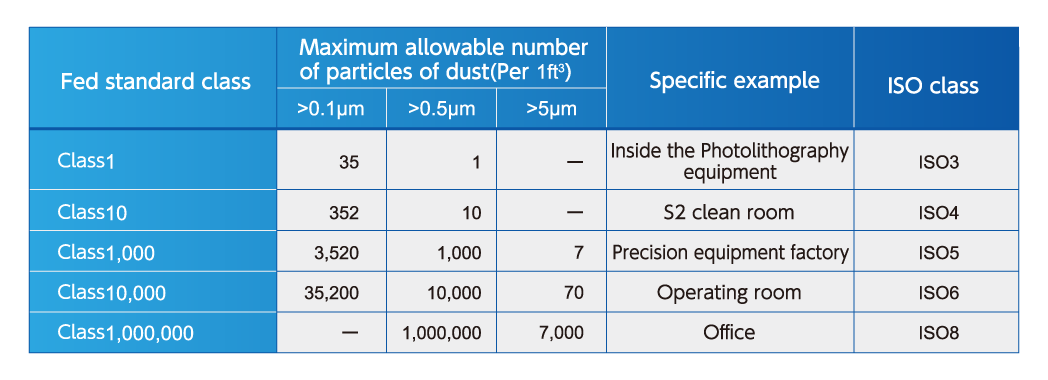

Cleanliness of the S2 Plant

Cleanliness

Our cleanroom is classified as class 10 according to the Federal Standard. This level of cleanliness doesn’t exist in nature.

Maintain cleanliness

Minimum line-width of LSIs fabricated at the S2 Plant is 0.1μm. If dust as large as its line-width adheres to the surface of semiconductors, it causes pattern defects. Constantly supplying air purified through HEPA filters helps keep the clean environment of the cleanroom.

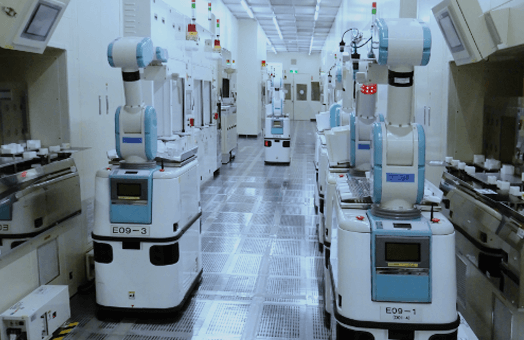

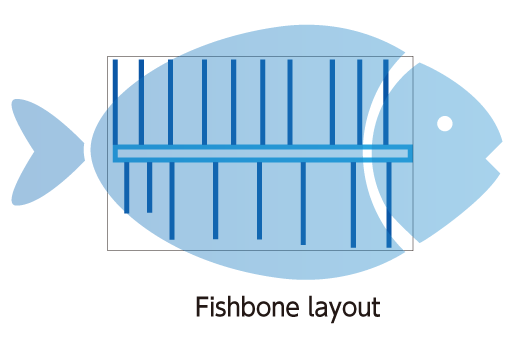

Conveyance System

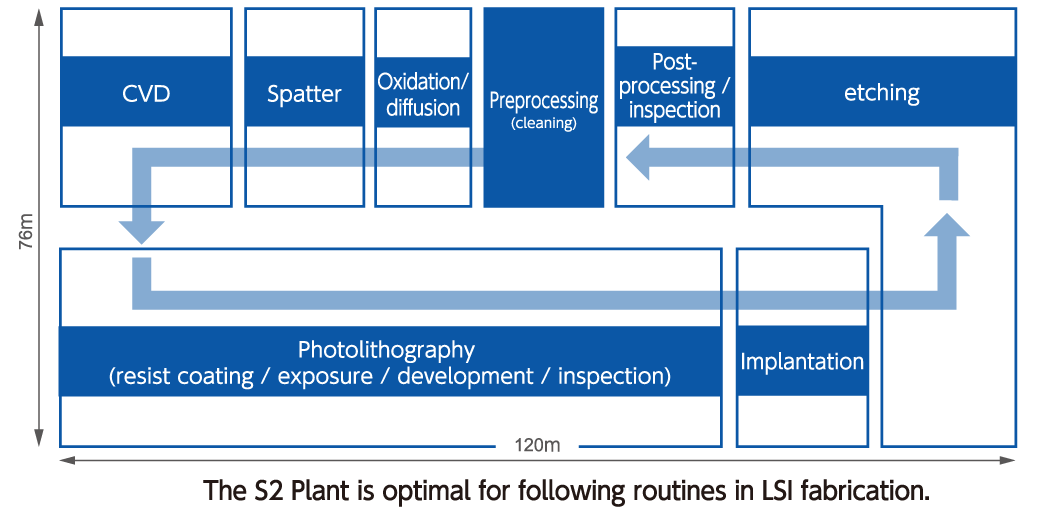

Fishbone layout is adopted to ensure effective conveyance and high productivity.

In-Plant Layout Tailored to LSI Fabrication Process

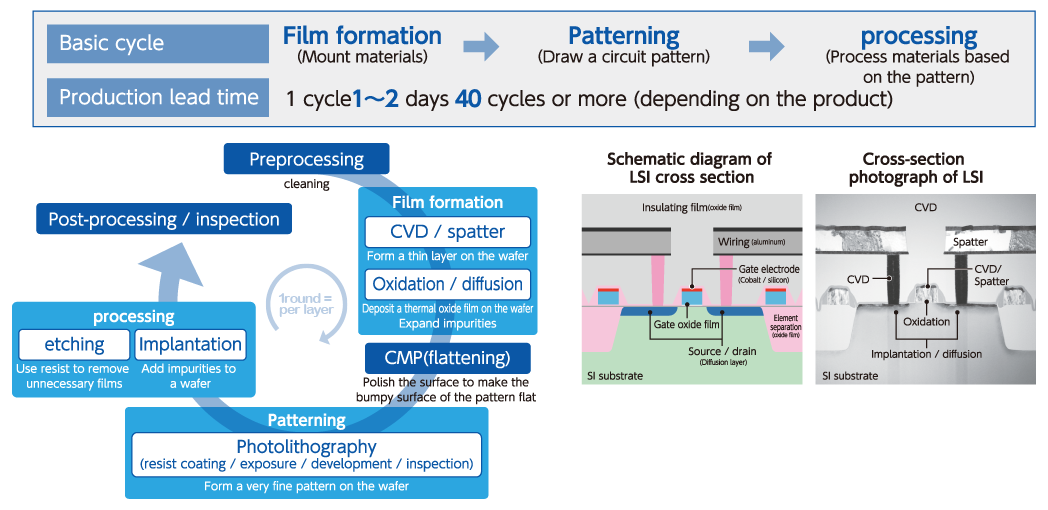

Following routines is fundamental in LSI fabrication.

LSI makes electric circuits by forming elements on silicon wafers and connecting elements with aluminum. Elemental technology for LSI fabrication is repeatedly used in the same order to form electric circuits.